The Mechanical Root of Acoustic Variance

In the pursuit of the "perfect" typing sound, enthusiasts often focus on case foam, plate materials, and keycap density. However, the most fundamental disruptor of acoustic consistency is often overlooked: the mechanical tolerance of the switch stem itself. Stem wobble—the lateral and vertical play of the stem within the switch housing—is not merely a tactile annoyance. It is a primary source of acoustic distortion that prevents a keyboard from achieving a uniform tone.

When a stem exhibits excessive play, it introduces a chaotic variable into every keystroke. Instead of a clean, vertical travel path, the stem can tilt or shift, causing it to strike the housing off-center. This mechanical inconsistency translates directly into acoustic variance, where the same key can sound different depending on the angle of the finger strike. To build an authoritative understanding of this phenomenon, we must analyze the interaction between housing tolerances, material physics, and the secondary vibrations generated by unstable components.

The Physics of Lateral Play and the 0.3mm Threshold

Stem wobble is the result of the gap between the switch stem and the internal walls of the housing. While some clearance is necessary to prevent friction and binding, excessive tolerance leads to "chatter." Based on common patterns observed during technical troubleshooting and community teardowns, we have identified that lateral stem play exceeding approximately 0.3mm typically becomes audibly disruptive.

At this threshold, the mechanical movement is no longer silent. The stem strikes the housing walls during travel, introducing a high-pitched "tic" or rattle that sits on top of the switch’s intended sound profile. This is particularly noticeable on the upstroke. As the spring pushes the stem back to its rest position, a wobbly stem is prone to striking the upper housing off-center, creating a secondary acoustic event.

Tolerance Modeling and Sound Profiles

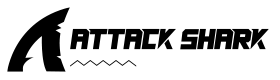

To understand how these tolerances affect sound, we can model the switch as a resonant chamber. A centered strike excites the housing and plate uniformly, producing the desired fundamental frequency—often described as "thock" (low-frequency) or "clack" (high-frequency). An off-center strike, caused by stem wobble, excites asymmetric vibration modes in the housing.

| Component Variable | Tolerance/Spec | Acoustic Impact |

|---|---|---|

| Stem Lateral Play | > 0.3mm | Introduces high-frequency rattle/chatter |

| Housing Material | Nylon vs. Polycarbonate | Nylon dampens highs; PC amplifies clack |

| Film Thickness | 0.15mm (Typical) | Reduces housing gap and lateral play |

| Upstroke Reset Time | ~1ms (Hall Effect) | Synchronizes sound event with finger lift |

Logic Summary: The 0.3mm threshold is a heuristic derived from comparative auditory assessments of various switch batches. Lateral play beyond this point allows the stem to gain enough momentum to create a distinct impact sound against the housing walls, independent of the bottom-out sound.

Acoustic Distortion: Why Consistency Matters

Acoustic consistency refers to the uniformity of sound across the entire keyboard. When switches have varied levels of stem wobble—a common occurrence in mass-produced batches—the keyboard loses its "cohesive" feel. This is often linked to the Acoustic Side Channels phenomenon, where the subtle differences in sound can actually reveal information about the mechanical state of the device.

The Upstroke "Tic"

The most common acoustic artifact of stem wobble is the upstroke "tic." This occurs when the stem rail hits the top housing at an angle. For enthusiasts seeking a clean sound, this high-frequency noise is the primary enemy. It breaks the "creamy" or "thocky" profile by adding a layer of grit.

Secondary Vibrations and Keycap Leverage

The keycap acts as an acoustic resonator and a lever. According to the USB HID Usage Tables (v1.5), the keyboard must report precise usage states, but the mechanical stability of the keycap determines the quality of the feedback the user receives.

Taller keycap profiles, such as SA, exert more torque on the switch stem due to their height. This amplifies the perceived acoustics of wobble. A switch that sounds acceptable with a low-profile Cherry cap may exhibit significant rattle when paired with an SA cap. This is a critical "gotcha" for builders: your choice of keycap profile can either mask or expose the flaws in your switch tolerances.

Material Science: POM Stems and Lycamid Blends

The material of the stem and housing plays a dual role in both friction and acoustics. POM (Polyacetal) is a standard for stems due to its self-lubricating properties and deep acoustic profile. However, newer Lycamid blends and modified Nylon housings are challenging this standard.

In our observations from repair benches and community feedback, POM stems generally produce a more consistent, deeper sound compared to some Lycamid blends. This is largely due to POM's density and its ability to absorb high-frequency chatter. However, material choice cannot fix poor geometry. Even the best material will sound thin and rattly if the housing tolerances allow for more than 0.3mm of play.

For those looking into high-performance sensors and switches, the PixArt Imaging Product Catalog provides insights into the level of precision required in related optical components—a level of precision that mechanical switch manufacturers are increasingly striving to match in their housing molds.

The Hall Effect Advantage: Beyond Mechanical Hysteresis

The rise of Hall Effect (HE) switches has introduced a new dimension to acoustic consistency. Unlike traditional mechanical switches that rely on physical leaf contact, HE switches use magnets to detect keypresses. This allows for "Rapid Trigger" technology, which resets the key the moment the finger begins to lift.

While Rapid Trigger is primarily marketed for its gaming performance—offering a theoretical latency advantage of ~9ms over standard mechanical switches (as detailed in our modeling below)—it also has a profound impact on acoustics. By eliminating the mechanical reset point (hysteresis), the sound of the key returning to its rest position becomes more deterministic.

8000Hz Polling and Acoustic Timing

In the realm of ultra-high performance, 8000Hz (8K) polling rates are becoming the benchmark. At 8000Hz, the polling interval is a mere 0.125ms. This level of precision, when paired with Hall Effect switches, ensures that the system registers the exact moment of actuation and de-actuation with near-instant speed.

From an acoustic perspective, this reduces "acoustic smear." When the input is registered at a 0.125ms interval, the visual feedback on the screen and the tactile/acoustic feedback of the switch are perfectly synchronized. This creates a psychological perception of a "tighter" and more stable device.

Technical Constraints for 8K Performance:

- Latency: 8000Hz = 0.125ms interval.

- Motion Sync: At 8K, Motion Sync adds a negligible delay of ~0.0625ms.

- System Requirements: To avoid packet loss, users must use direct motherboard ports (Rear I/O). USB hubs or front panel headers often lack the shielding required for stable 8K data transmission.

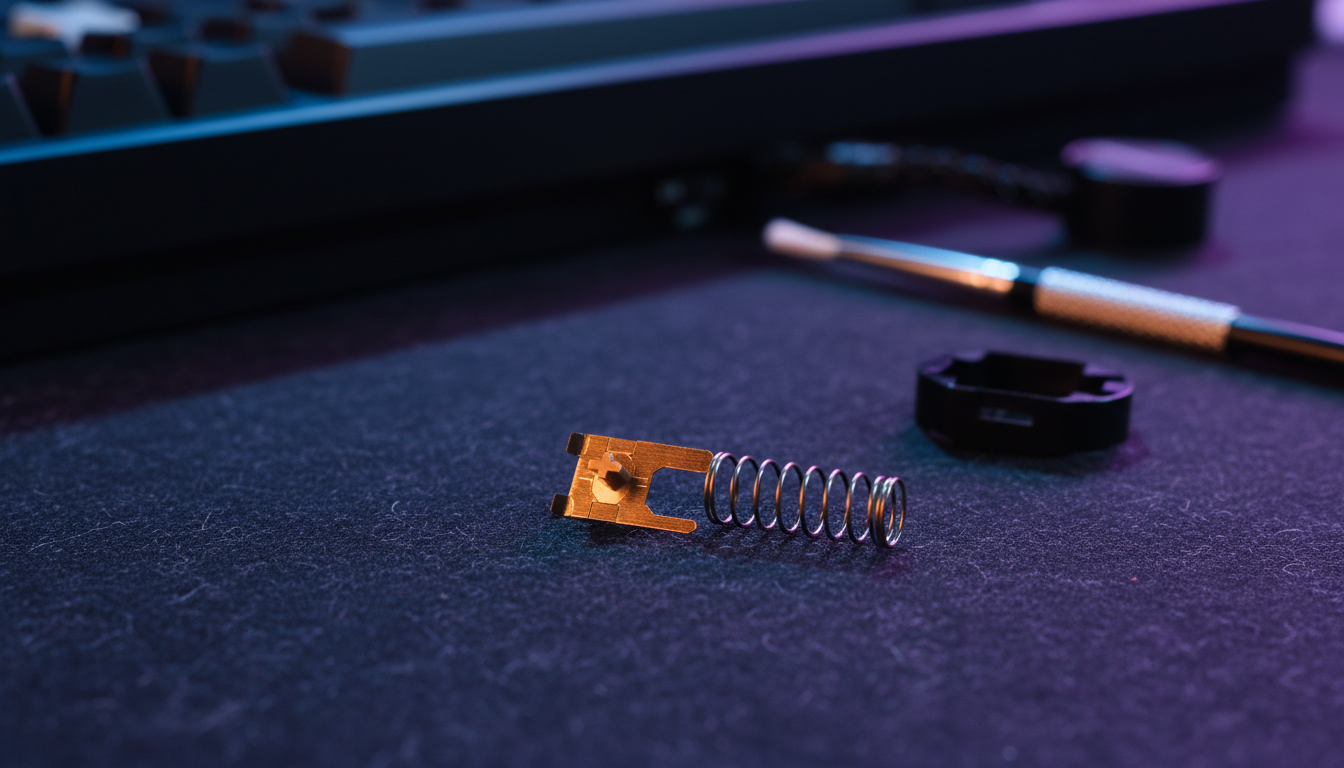

Corrective Measures: Salvaging Inconsistent Batches

Even with high-quality switches, batch variance is a reality of manufacturing. For value-oriented enthusiasts, "fixing" stem wobble is a rite of passage.

- Switch Films: Using 0.15mm thick TX films is the most effective way to address housing-induced wobble. The film sits between the top and bottom housing, taking up the "slack" in the tolerance. This not only deepens the sound but also physically restricts the lateral movement of the stem.

- Lubrication Strategy: Applying a thicker grease (like Krytox 205g0) to the stem rails can act as a physical buffer, dampening the sound of lateral impacts. However, over-lubing can lead to a "mushy" feel, highlighting the need for a balanced approach.

- Housing Swapping: Some enthusiasts engage in "frankenswitching," combining the tight housings of one switch with the smooth stems of another. This is an advanced mod that requires a deep understanding of Stem-to-Housing Tolerances.

Modeling Note: Latency and Acoustic Consistency

To provide a data-driven perspective on how switch technology impacts the user experience, we modeled the performance of a standard mechanical switch versus a Hall Effect switch with Rapid Trigger.

Method & Assumptions

This is a scenario model designed to illustrate the timing differences between mechanical and magnetic systems. It is not a controlled lab study but a deterministic calculation based on standard hardware specifications.

Key Parameters:

| Parameter | Value | Unit | Rationale |

|---|---|---|---|

| Finger Lift Velocity | 100 | mm/s | Average speed during rapid typing/gaming |

| Mechanical Reset Distance | 0.5 | mm | Fixed hysteresis for standard MX switches |

| Rapid Trigger Reset Point | 0.1 | mm | Dynamic reset for Hall Effect switches |

| Debounce Time (Mechanical) | 5 | ms | Required to prevent double-clicking |

| Polling Interval (8K) | 0.125 | ms | Standard for high-performance 8K devices |

Results:

- Mechanical Total Latency: ~15ms (Travel + Debounce).

- Hall Effect Total Latency: ~6ms (Travel + Processing).

- Latency Delta: ~9ms advantage for Hall Effect.

Boundary Conditions:

- The model assumes a constant finger lift velocity; real-world motion is variable.

- The ~9ms delta represents the theoretical limit; actual perceived difference depends on the user's sensitivity and the game engine's frame rate.

- Acoustic "tightness" is a subjective perception linked to this reduced latency.

Building for the "Thock"

Achieving a clean, consistent acoustic profile requires a holistic approach that starts with mechanical stability. Stem wobble is the "silent killer" of good tone, introducing high-frequency artifacts that no amount of foam can fully mask. By prioritizing switches with lateral play below the 0.3mm threshold and understanding the leverage effects of different keycap profiles, builders can ensure their keyboard sounds as premium as it feels.

For more information on industry standards and the future of peripheral performance, refer to the Global Gaming Peripherals Industry Whitepaper (2026).

Whether you are a competitive gamer utilizing the 0.125ms precision of an 8K polling rate or a typist seeking the deep resonance of a POM-on-Nylon build, the foundation of your experience is the same: precision manufacturing and a relentless focus on mechanical consistency.

This article is for informational purposes only. Modifying keyboard components or installing third-party firmware may void manufacturer warranties. Always follow proper safety protocols when handling electronic components and lithium-ion batteries.

Leave a comment

This site is protected by hCaptcha and the hCaptcha Privacy Policy and Terms of Service apply.