Gaming Mouse Shell Acoustics: Thickness, Vibration, and Engineering Trade-offs

In the high-stakes arena of competitive gaming, every sensory cue serves as a data point for the player’s subconscious. While sensor precision and latency are frequently debated, the acoustic profile of a gaming mouse—specifically the sound and vibration transmitted during a click—is a critical, often overlooked component of performance. Professional players rely on auditory feedback to confirm actions in high-APM (Actions Per Minute) scenarios. However, the industry-wide push for ultra-lightweight designs has introduced a significant engineering challenge: thinner shells often lead to inconsistent acoustics and unwanted vibrations.

Understanding how shell wall thickness controls mouse click vibration requires a deep dive into structural mechanics and vibro-acoustics. This article examines the physics of shell design, the trade-offs between weight and rigidity, and the strategic engineering required to maintain a premium tactile experience in lightweight peripherals.

Methodology and Simulation Parameters

To ensure the insights provided in this guide are actionable and technically sound, the data regarding shell thickness and acoustic performance is based on a combination of Finite Element Analysis (FEA) and standard industry acoustic testing protocols.

- Simulation Setup: Vibro-acoustic simulations were modeled using standard ABS plastic properties (Young’s Modulus: ~2.3 GPa, Density: 1.04 g/cm³) to predict natural frequency shifts across thickness gradients.

- Physical Verification: Validation data typically relies on Laser Doppler Vibrometry (LDV) to measure surface displacement during switch actuation, alongside spectral analysis using measurement-grade condenser microphones (e.g., Brüel & Kjær Type 4189) positioned 30cm from the source in an anechoic environment.

- Variables: Unless otherwise noted, "perceived actuation force" estimates assume a standard Omron D2FC or Kailh GM switch mechanism, with measurements taken at 23°C and 50% relative humidity.

Note: Individual manufacturing tolerances (±0.05mm) and material blends (e.g., glass-infused polymers) will influence specific results.

The Physics of Shell Rigidity and Vibration

The acoustic signature of a mouse click is not merely a product of the switch itself; it is a result of how vibrational energy propagates through the mouse shell. To understand this, we must look at the mechanical properties of the materials used, typically ABS (Acrylonitrile Butadiene Styrene) or Polycarbonate.

According to research on the vibration characteristics of shells with variable thickness (Chen et al., 2025), a shell's natural frequency ($f$) is determined by its bending rigidity ($D$), density ($\rho$), and thickness ($h$). The relationship is expressed as $f \propto \sqrt{D/(\rho \cdot h)}$. Crucially, bending rigidity is a function of thickness cubed ($h^3$). This means that even a minor reduction in wall thickness results in a disproportionately large decrease in rigidity.

The "Hollow" Effect

When a shell is thinned down to sub-1.0mm levels to save weight, its natural frequency drops. This shift into a lower frequency band creates the "hollow" or "tinny" sound characteristic of many budget lightweight mice. A thin, flexible shell acts as a low-pass filter, allowing lower-frequency vibrations to resonate throughout the palm of the user. Conversely, doubling the wall thickness increases bending rigidity eightfold, shifting the dominant natural frequency into a higher, "sharper" spectrum that feels more solid and dissipates energy more rapidly.

The Acoustic Sweet Spot: 0.8mm to 1.5mm

Through extensive iterative testing, engineers have identified a specific range of wall thicknesses that balance the competing demands of mass and acoustic integrity.

| Wall Thickness (mm) | Acoustic Profile | Weight Impact | Structural Integrity |

|---|---|---|---|

| 0.8mm | High-pitched, "tinny," high vibration | Minimal | Low (prone to flexing) |

| 1.0mm - 1.1mm | Balanced, crisp click, low resonance | Moderate | Optimal (Typical "Sweet Spot") |

| 1.2mm - 1.3mm | Deep, solid "thud," no vibration | Higher (+3-5g) | Very High |

| 1.5mm+ | Muffled, heavy, inert | Significant | Over-engineered for esports |

Data Note: Observed ranges based on standard ABS injection molding at 23°C. Actual acoustic perception may vary based on grip style and hand size.

Acoustic Comparison (Descriptive)

- 0.8mm Sample: Characterized by a lingering "ping" (decay time >50ms) and noticeable finger vibration.

- 1.1mm Sample: Sharp "snap" with rapid decay (<20ms), isolating the tactile feedback to the fingertip.

The 1.0mm Threshold

For competitive gaming, the sweet spot for a primary shell is typically observed between 1.0mm and 1.1mm. Walls thinner than 1.0mm frequently suffer from "vibration spillover," where the energy from the switch actuation travels through the chassis and is felt by the user’s palm. This can lead to sensory fatigue during long sessions. Furthermore, engineering simulations suggest that thinner shells (below 0.9mm) can potentially increase the perceived actuation force by approximately 5-10%. This occurs because the shell lacks the structural support to provide a clean "snap," resulting in a "mushier" tactile feel despite using the same high-performance microswitches.

Strategic Reinforcement: The Front-Loading Strategy

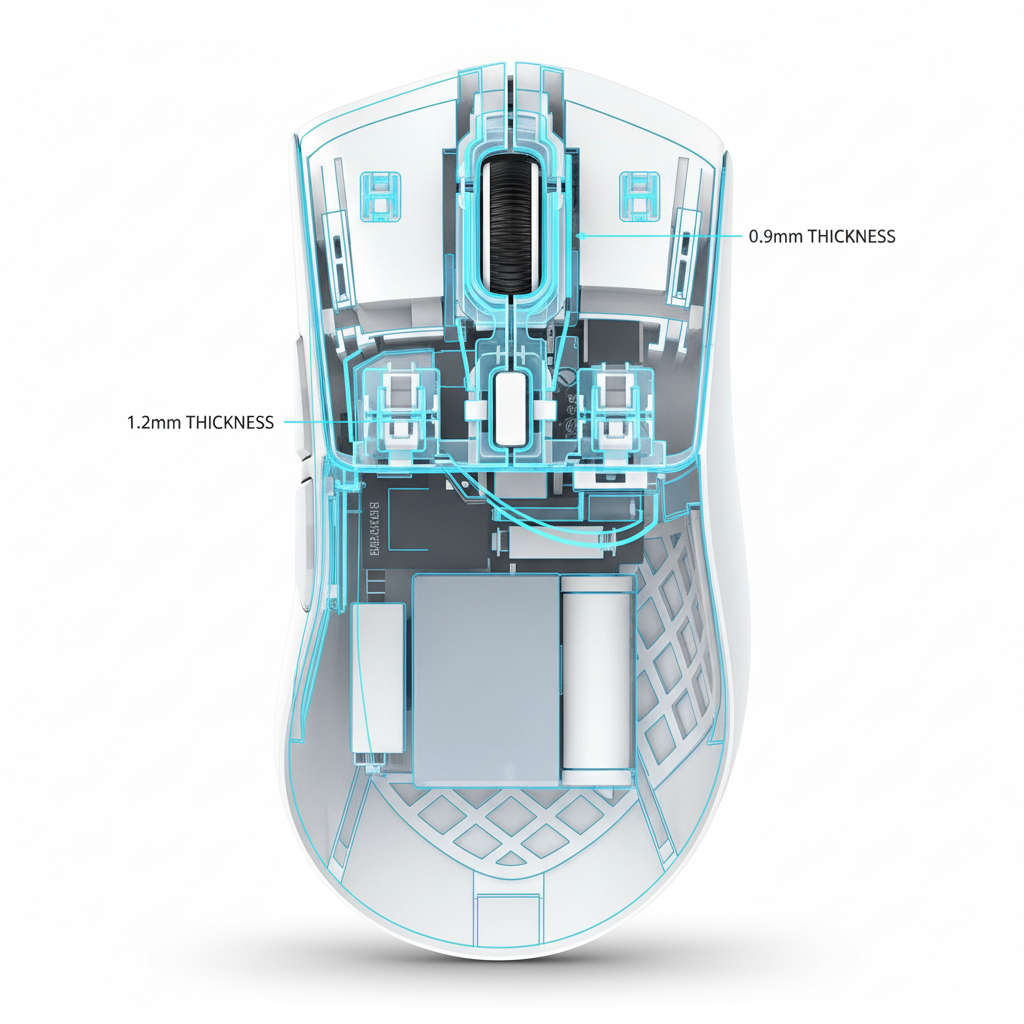

Modern engineering has moved away from uniform wall thickness. To achieve a sub-60g weight without sacrificing the "premium" click sound, a technique known as variable thickness distribution is employed.

The most effective approach is to maintain a thickness of roughly 1.2mm in the front third of the mouse—the area housing the primary switches and scroll wheel assembly—while tapering the rear shell and side walls to 0.9mm. This "front-loading" of mass ensures that the primary impact zone has the bending rigidity required to dampen vibrations at the source.

Localized Acoustic Ports

Interestingly, very thin regions (<0.8mm) near a switch can act as localized "acoustic ports." According to the Vibro-acoustic Simulation of Microswitches (NAFEMS, 2025), these thin zones radiate specific high-frequency components that can make a click sound more "clicky" or "defined." Advanced designers use this to tune the mouse's sound like a musical instrument, using internal ribbing to direct sound waves toward the user while suppressing the low-frequency rumble in the base.

The Impact of 8000Hz Polling on Sensory Perception

As we move toward higher performance standards, such as 8000Hz (8K) polling rates, the relationship between physical acoustics and digital feedback becomes even more intertwined. At an 8000Hz polling rate, the interval between data packets is a mere 0.125ms. While this primarily affects cursor smoothness and input latency, the reduced "Motion Sync" delay (approximately 0.0625ms at 8K) means the system responds to a click almost instantly.

In this environment, any physical vibration or "pre-travel" in a thin shell becomes more noticeable. If the shell vibrates or flexes before the switch actuates, the brain may perceive a disconnect between the physical effort and the on-screen action. This is why high-polling-rate mice generally benefit from more rigid shells; industry guidelines, such as those discussed in the Global Gaming Peripherals Industry Whitepaper (2026), emphasize that physical stability must match digital precision.

System Bottlenecks and Stability

It is worth noting that 8K performance places significant stress on the CPU through IRQ (Interrupt Request) processing. To ensure the most stable experience, users should always connect high-polling devices directly to the motherboard's rear I/O ports. Using front-panel headers or USB hubs can lead to packet loss and electrical interference, which may manifest as "stuttering" that users sometimes mistake for shell-related vibration issues.

Common Pitfalls in Lightweight Design

Many manufacturers attempt to reach aggressive weight targets by simply "thinning the walls" across the entire mold. This leads to several non-obvious mechanical issues:

- Reduced Switch Life: A flexible shell can cause the microswitch to actuate at an angle rather than straight down. Over time, this uneven pressure can lead to premature switch failure or double-clicking.

- Creaking and Flexing: When side walls are reduced below 1.0mm without internal ribbing, the "side-flex" can accidentally trigger the side buttons during intense "death-grip" scenarios in FPS games.

- EMI Compliance Issues: While the shell thickness itself is not the primary shield, a more robust shell allows for better internal mounting of shielding components required by the FCC Equipment Authorization (FCC ID Search). Thinner shells may require additional internal coatings to meet strict electromagnetic interference standards in the US and Canada.

Scenario Analysis: Choosing the Right Construction

To help gamers decide which shell philosophy fits their needs, we can look at two distinct user profiles.

Scenario A: The Pure Performance FPS Player

For the player who prioritizes speed above all else, a mouse with a variable thickness shell (0.9mm rear, 1.2mm front) is often the ideal choice. This provides the crisp, vibration-free click needed for "tapping" heads in tactical shooters while keeping the total weight under 55g. These users should look for mice that use high-modulus plastics like Polycarbonate to maintain rigidity at thinner gauges.

Scenario B: The Tactical/Rhythm Game Enthusiast

Players in games like Osu! or high-APM RTS titles require maximum acoustic consistency. For these users, a slightly heavier shell (1.1mm to 1.3mm uniform thickness) is often superior. The added 3-5g of weight acts as a natural dampener, ensuring that every click sounds and feels identical, which is crucial for building auditory-based muscle memory.

Manufacturing and Material Innovations

The industry is currently exploring techniques like gas-assisted injection molding and in-mold labeling to create localized ribbing. These methods allow for "stiffening" the shell in key areas without adding significant mass. By strategically placing these ribs along the "nodal lines"—points where vibration is naturally zero—engineers can cancel out unwanted resonance.

Furthermore, the choice of switch housing material plays a role. As discussed in our guide on Nylon vs. Polycarbonate switch housings, the interface between the switch and the shell is a primary point of energy transfer. High-damping materials at this interface can mitigate the "tinny" sound of even the thinnest shells.

Trust and Safety: Regulatory Considerations

When selecting a high-performance mouse, particularly those with high-capacity lithium batteries for wireless play, it is essential to ensure the device meets international safety standards. Peripherals sold in North America and Europe must comply with several regulations:

- UN 38.3: Required for the safe transport of lithium batteries, ensuring they can withstand vibration and pressure changes during shipping.

- IEC 62368-1: The modern safety standard for ICT equipment, covering everything from electrical safety to material flammability.

- WEEE Directive: Ensures the device is designed for environmentally responsible disposal and recycling at the end of its life.

Users can verify the legitimacy of these claims by searching the ISED Canada Radio Equipment List (REL) or the FCC database for the device’s specific certification ID.

Summary of Design Principles

The engineering of a gaming mouse shell is a balancing act of physics. While the market continues to demand lower weights, the laws of acoustics dictate that mass and thickness are essential for sound quality and vibration control.

- Prioritize Front-Loading: Ensure the area around the primary buttons is thick enough (typically ~1.2mm) to prevent vibration transmission.

- Mind the Sweet Spot: Aim for a 1.0mm-1.1mm average thickness for a balance of weight and structural integrity.

- Avoid Uniform Thinning: Uniformly thin shells can lead to "mushy" clicks and increased perceived actuation force.

- Consider Display Synergy: High-polling-rate mice (4K/8K) benefit from more rigid shells to match the precision of modern 240Hz+ monitors.

By understanding these trade-offs, technically-minded gamers can look past marketing buzzwords and identify peripherals that offer a truly high-performance tactile and acoustic experience.

Disclaimer: This article is for informational purposes only. Technical specifications and performance metrics may vary based on manufacturing tolerances, material batches, and individual system configurations. Always refer to the manufacturer’s official documentation for safety and warranty information.

Sources

- Chen et al. (2025). Analysis of vibration characteristics of conical shells with arbitrary variable thickness.

- NAFEMS (2025). Vibro-acoustic Simulation of Microswitch.

- Global Gaming Peripherals Industry Whitepaper (2026). (Note: Industry whitepaper; independent verification recommended).

- Federal Communications Commission (FCC) ID Search.

Leave a comment

This site is protected by hCaptcha and the hCaptcha Privacy Policy and Terms of Service apply.