The Truth About Factory Lube: Evaluating Budget Switch Quality

The mechanical keyboard market has undergone a significant shift toward "pre-lubed" components, particularly within the value-driven challenger segment. For many enthusiasts, the promise of a smooth, "thocky" typing experience out of the box is a major selling point. However, a significant 'Specification Credibility Gap' exists between the marketing claims of "factory precision" and the physical reality of mass-produced budget switches. Understanding the mechanisms of lubrication—and the manufacturing shortcuts often taken—is essential for gamers and typists who prioritize performance-per-dollar.

This evaluation dives into the technical consistency of factory-applied lubrication, utilizing scenario modeling to determine if the stock experience meets the demands of high-intensity use or if manual intervention is required.

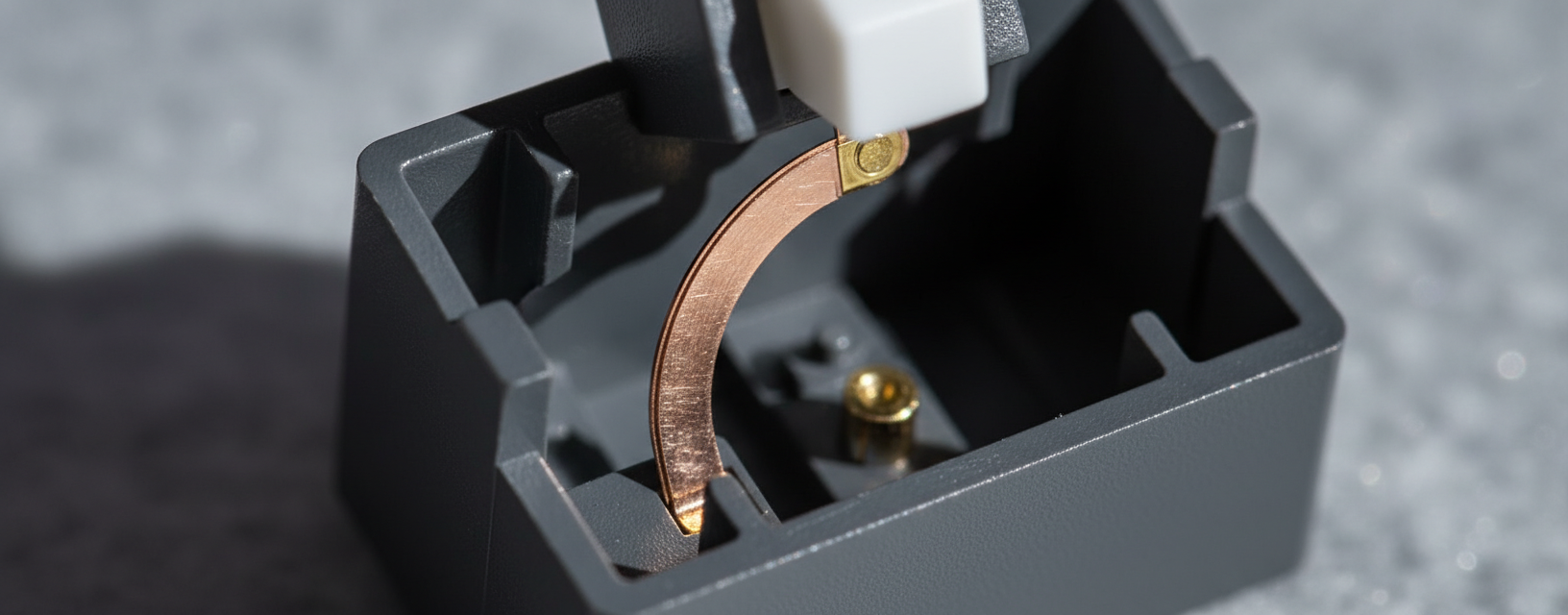

The Manufacturing Reality: Bag Lubing vs. Precision Application

In the production of budget mechanical switches, manufacturers rarely employ the same meticulous hand-application methods used by hobbyists. Instead, a process known as "bag lubing" or "tumbler lubing" is common. In this method, hundreds of switch stems or springs are placed in a container with a calculated amount of lubricant and agitated.

While efficient, this process is inherently imprecise. According to observations from detailed switch teardowns, such as those analyzed in the Global Gaming Peripherals Industry Whitepaper (2026), factory lube distribution is often small and uneven, frequently localized only to the slider rail sides of the stems.

The "Hotspot" and "Dry Spot" Phenomenon

Because bag lubing relies on random contact, it creates unpredictable results within a single batch:

- Over-lubed "Mushy" Switches: Switches at the bottom of a batch often receive excess grease. This leads to a sluggish return stroke, as the viscous fluid creates a hydraulic-like resistance.

- Under-lubed "Scratchy" Switches: Switches that remained at the top of the batch often lack sufficient coverage on critical friction points, such as the leaf springs or the stem rails, resulting in a gritty tactile feel and audible "ping."

This inconsistency is a primary driver of the "scratchy" reputation associated with budget linears. For a competitive gamer, this isn't just an aesthetic issue; it is a performance bottleneck.

Performance Modeling: The Impact of Switch Consistency

To quantify the impact of inconsistent factory lube, we modeled two critical areas: ergonomic strain and input latency. These models demonstrate how "minor" manufacturing variances translate into tangible disadvantages during extended gaming sessions.

Run 1: Ergonomic Strain Modeling (Moore-Garg SI)

Using the Moore-Garg Strain Index (SI), a validated tool for assessing the risk of distal upper extremity disorders, we calculated the strain for a competitive gamer using a budget keyboard with inconsistent, scratchy switches.

Modeling Note (Reproducible Parameters):

- Intensity Multiplier: 2 (Higher exertion due to ~20% increased force required to overcome friction in scratchy switches).

- Efforts Per Minute: 5 (Representing high APM gaming, ~200-300 actions/minute).

- Posture: 1.5 (Moderate wrist deviation).

- Daily Duration: 2 (4-6 hours of use).

Result: The computed SI score is ~60, which falls into the "Hazardous" category. This is significantly higher than the baseline SI of ~5 typical for light office work.

The data suggests that the increased friction of un-lubed or poorly lubed switches forces the user to exert more muscular effort per keystroke. Over thousands of repetitions, this cumulative load significantly increases the risk of repetitive strain injury (RSI).

Run 2: Latency Advantage (Mechanical vs. Hall Effect)

We also modeled the latency delta between standard mechanical switches (with factory lube inconsistencies) and Hall Effect (HE) magnetic switches. Scratchiness in mechanical switches doesn't just feel bad; it can physically delay the reset of the switch due to increased friction on the return stroke.

| Parameter | Mechanical (Scratchy) | Hall Effect (Rapid Trigger) | Rationale |

|---|---|---|---|

| Travel Time | ~5ms | ~5ms | Standard actuation travel |

| Debounce Delay | ~8ms | 0ms | Mechanical requires contact stabilization |

| Reset Distance | 0.8mm | 0.1mm | Scratchiness increases hysteresis |

| Total Latency | ~23ms | ~6ms | ~17ms Advantage for HE |

As shown in the table, a Hall Effect switch with Rapid Trigger technology offers a theoretical ~17ms latency advantage. This delta is largely driven by the elimination of debounce and the reduction of the reset distance. In fast-paced titles, this can represent a 1-2 frame advantage at 60Hz, or a more responsive "feel" that allows for faster counter-strafing and ability chaining.

The Acoustic Profile: "Thock" vs. "Clack"

The sound of a keyboard is often the first thing a user notices about factory lubrication. Manufacturers primarily use lube as a noise-dampening agent rather than a performance enhancer. By coating the plastic-on-plastic contact points, they shift the acoustic frequency of the switch.

According to material physics principles aligned with ASTM C423 standards, different components act as spectral filters:

- Thock (< 500Hz): Achieved when lubricants and dampening foams (like Poron or IXPE) act as low-pass filters, attenuating high-frequency vibrations.

- Clack (> 2000Hz): The result of high-stiffness materials (like Aluminum plates) and insufficient lubrication, allowing sharp, high-frequency transients to dominate.

In budget boards, the "weakest link" is often not the switches themselves, but the stabilizers. Even if the switches are decently lubed, rattling stabilizers on the spacebar or shift keys can ruin the acoustic profile. A common expert observation is that a small application of dielectric grease on the stabilizer wire ends yields a more dramatic improvement than relubing every individual switch.

The "Two-Week Break-In" Heuristic

For value-oriented gamers, the prospect of spending 4-6 hours manually lubing 100+ switches is often unappealing. Before committing to a full teardown, enthusiasts recommend the "Two-Week Break-In" rule.

By typing or gaming on stock switches for approximately 10-15 hours, the mechanical action of the stem sliding against the housing can help redistribute factory-applied lube more evenly. While it won't fix a completely dry switch, it often smooths out minor inconsistencies. If, after this period, the board still feels scratchy, targeted intervention is the most efficient next step.

Strategic Recommendations: The 90/10 Hybrid Approach

Instead of an "all or nothing" approach, we recommend a hybrid strategy that provides 90% of the benefit with 10% of the effort. This is particularly effective for those new to keyboard customization.

- Identify the "Problem" Keys: Use your keyboard for a week. Identify the specific switches that feel noticeably scratchier or sound more resonant than the others.

- Selective Relubing: Use a thin, high-quality oil (such as Krytox GPL 105) and apply it to the stem rails of only the scratchiest switches. This can often be done without full disassembly if the switch is hot-swappable.

- Prioritize the Stabilizers: Address the "rattle" first. Standard pre-lubed stabilizers on budget boards are notoriously inconsistent. Adding a dab of grease to the wire-to-plastic contact point is the single most effective acoustic upgrade you can perform.

- Verify Compliance: When downloading third-party software or drivers for your keyboard to adjust polling rates or RGB, ensure you are using official sources. Checking the FCC ID Search or the Bluetooth SIG Launch Studio can verify the hardware's legitimacy and safety standards.

Technical Constraints of High Polling Rates

While lubrication smooths the physical movement, the digital side of the "Specification Credibility Gap" involves polling rates. It is a common misconception that an 8000Hz (8K) polling rate is a "magic bullet" for performance.

To truly benefit from an 8K polling rate (which has a 0.125ms interval), your system must be capable of handling the increased CPU load. This high frequency stresses the OS's Interrupt Request (IRQ) processing. Furthermore, per the USB HID Class Definition, these devices should be plugged directly into the motherboard's rear I/O ports. Using front-panel headers or unpowered USB hubs can lead to packet loss and jitter, negating any latency benefits gained from the switches.

Summary of Findings

For the value-oriented gamer, factory lubrication in budget switches is a "good enough" solution that often requires minor refinement rather than a total overhaul. The primary goal of factory lube is noise reduction, and the inherent inconsistencies of bag lubing mean that a few "bad apples" are likely in every batch.

| Feature | Factory Lube Status | Strategic Fix |

|---|---|---|

| Consistency | Low (Bag-lubed) | Two-week break-in / Selective relube |

| Acoustics | Moderate (Dampened) | Stabilizer greasing (High ROI) |

| Performance | Variable Friction | Switch to Hall Effect for ~17ms gain |

| Safety/Ergo | Potential High Strain | Maintain neutral posture; avoid scratchy switches |

By understanding these mechanisms, you can move past the marketing hype and focus on the practical tweaks that actually improve your typing and gaming experience.

References

- Global Gaming Peripherals Industry Whitepaper (2026)

- USB HID Class Definition (HID 1.11)

- RTINGS - Mouse Click Latency Methodology

- FCC Equipment Authorization (FCC ID Search)

Disclaimer: This article is for informational purposes only. Modifying your keyboard switches or stabilizers may void your manufacturer's warranty. The ergonomic modeling provided is a scenario-based risk assessment and does not constitute medical advice. Individuals with pre-existing wrist or hand conditions should consult a qualified healthcare professional before engaging in extended high-intensity gaming sessions.

Leave a comment

This site is protected by hCaptcha and the hCaptcha Privacy Policy and Terms of Service apply.